List of Machinery

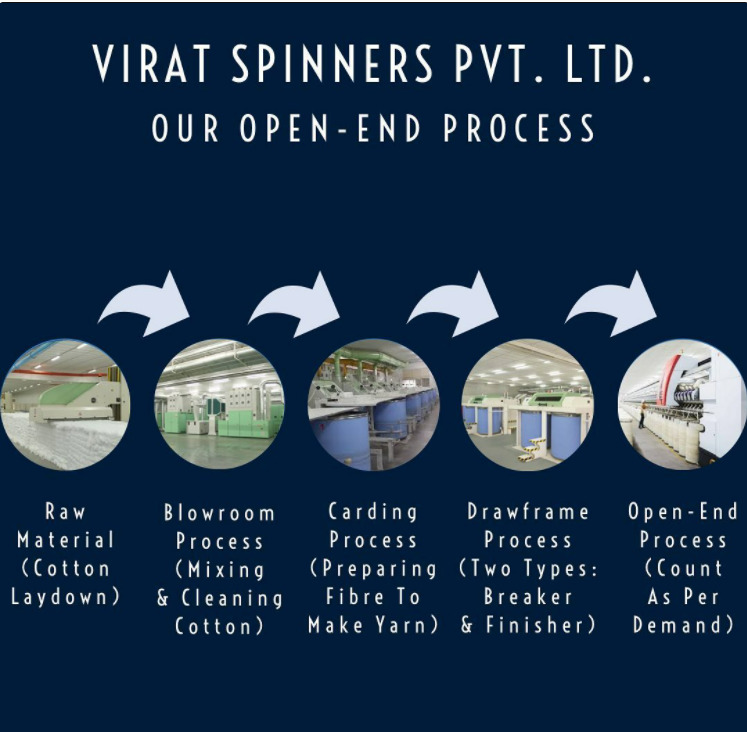

- LMW Make Blow Room Line with

- Bale Plucker LA 23 – 1 Pc

- Varioclean LB 9/2 – 1 Pc

- Unimix LB 7/4 – 1 Pc

- Suprimoclean LB 10 – 2 Pcs

- Metal & Fire Detector (ELGI) – 4 Pcs

- Premier i-Qube Contamination Removing Machine With UV light and colored fiber detection technology – 1 Pc

- LMW Make LC 363 Card – 10 Pcs (With Fine Feed LA 7/6 & Automatic Can Changer)

- LMW Make LD2 Breaker Draw Frame – 2 Pcs

- LMW Make RSB-851 Draw Frame – 4 Pcs (With Auto-Leveller)

- Truetzschler Make TD 08 Draw Frame – 1 Pc

- Saurer Schlafhorst German Make Auto Coro 8 (ACo-8) – 2 Pcs (480 rotors with corolab clearing system, auto piecing individual rotor)

- Saurer Schlafhorst German Make Se-11 & 12 Hybrid Model – 1 Pc (192 rotors with Uster yarn clearing system, auto piecing)

Total Rotors installed – 1152 rotors

Other Machinery

- Batliboi Waste Collection System

- Batliboi Humidification Plant

- Elgi Yarn Conditioning Plant

- Kaeser Compressor

Testing Equipment

- USTER HVI 1000 for cotton testing parameters

- Mag trash machine to check cotton trash

- MAG CSP tester for yarn csp checking

- Premier IQ2 LX for U% and IPI testing of Yarn